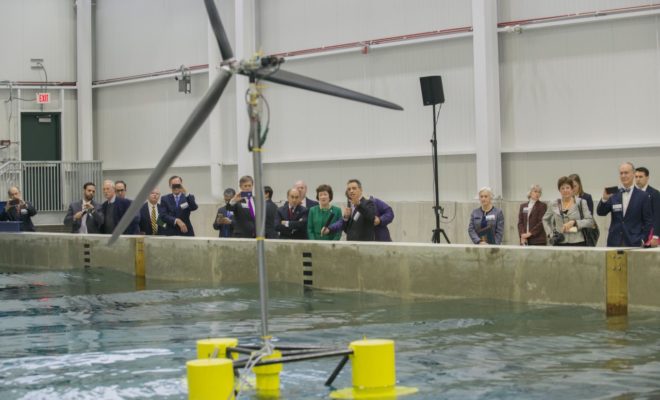

FORCES TO RECKON WITH: In a first, simulator generates both wind and waves to test structural strength against ocean forces

Posted

Last Updated

By Laurie Schreiber

SHIPS, OIL RIGS, OFFSHORE WIND TURBINES,

BRIDGES, SEA WALLS: whether on the high seas

or close to home, they are all subjected to elemental

forces. They exist in an environment that tests human

ingenuity on the calmest day as well as during nature’s battering

fury.

The dilemma is how to test designs for these structures

ahead of time. A multi-million-dollar facility at the University

of Maine’s Advanced Structures and Composites

Center in Orono, Maine, is a part of the solution. Its

founders say it is the world’s first combined wind-and-wave

simulator.

“Around the world, there are wind tunnels and wave

basins built for a variety of purposes. But no one, before this,

has put them together,” says UMaine Composites Center

founding director Habib Dagher, who led the effort to construct

the facility, called the Harold Alfond W2 Ocean Engineering

Laboratory.

The Olympic-pool-size basin is capable of simulating

any wind and wave scenario imaginable—hurricane-force

winds, wave heights of 120 to 130 feet, confused seas, shifting

wind direction—at a scale of 1 to 50.

“If you want to test a 300-foot-long ship, divide that by

50 and build a 6-foot model,” says Dagher. “If you want to

use that ship in 300 feet of water, divide 300 feet by 50, and

the basin depth needs to be a 6-foot depth.”

W2 is a 100-foot by 30-foot basin equipped with a

multi-paddle wave maker at one end, capable of creating

waves of varying frequency. The system also incorporates

a rotatable open-jet wind tunnel, a concrete floor that moves up and down to model a variety of depths up to 750

feet, and a tow carriage.

The need for W2 became apparent in 2008, when the

lab was commissioned to test a floating offshore wind turbine

for durability in wind and waves. Dagher and his team

searched the world for a combined facility, with no results.

For that contract, they designed a limited wind machine at

a marine facility in Europe. When they subsequently surveyed

more than 50 companies across the nation in various

industries—including shipbuilding, ocean energy, offshore

wind tidal energy, oil and gas, aquaculture, and civil infrastructure—

they realized there was great potential for a purpose-

built facility.

The idea was to build a dual facility, with W2 adjacent to

a manufacturing plant, the Harold Alfond Advanced Manufacturing Laboratory, that could build prototype test models in as little as a week’s time using advanced materials and techniques, including 3D printing and thermoplastic-formation.

(Thermoplastics are polymers that become moldable

above a certain temperature.)

“Let’s say you have a ship and you’re interested to see

how well the ship will do in a variety of ocean environments,”

says Dagher. “Having the ability to model both the

wind and wave environment simultaneously is unique.”

Building the W2 facility required the development of

new engineering and construction techniques. For example,

the basin incorporates a beach at one end that “kills”

the waves when they hit its perforated structure.

“When you’re applying waves in a basin, the waves travel

from one end to the other end. You don’t want the wave to

reflect back, or that will affect the accuracy of your results,”

Dagher says. “You want the wave to go, but never come

back. We spent a lot of time devising a beach design that

allows us to attenuate the wave within a short distance.”

Likewise, figuring out how to make the basin floor

move was no simple feat. Dagher and his team learned

about a steel floor that moved via a hydraulic system, but

at $1 million it was too expensive. Then they designed and

built the nation’s first floating wind turbine, using floating

and lightweight concrete technology, and realized the same

technology could be used for the W2 floor.

“It priced out at $150,000—and it’s a unique construction,”

Dagher says.

Construction of the wind wall also required considerable

invention. Whereas most wind tunnels provide constant

wind speed, W2’s rotating wind wall—comprising

multiple jets set in a compartmentalized wall at one end of

the basin—accurately models the increase in wind speed

that occurs with greater elevation, and it provides for shifts

in wind direction.

“When you provide a wind regime over a wave basin,

the wind regime has to follow strict requirements in terms

of accuracy and turbulence of the wind,” Dagher says.

“When you design something that’s bigger than a dump

truck that rotates, that’s significant. There’s no off-the-shelf

design out there that rotates to increase wind speed.”

Boatbuilders are among those who expressed great

interest in W2, Dagher says.

“A boatbuilder can test a new design in terms of its seakeeping

capability. Or, say you have a new design for a sailboat

for the America’s Cup. You can build a model and subject

it to a variety of wave and wind environments.” Overall,

he says, the facility has great potential for Maine. “Our

ocean-based economy is a big part of the overall economy.

This is a big deal for a state that relies on the ocean.” ■Excerpted from Boats of the Year 2016. Click here to read more stories from the latest edition.