In terms of unknown, unloved, and uncared-for naval engineering heroes, it’s tough to beat chainplates. That’s right, chainplates. The deeply-engineered chunks of metal or space-age composites that join hulls to rigging and masts. Chainplates aren’t exactly flashy. They do none of the sexy “sail-ish” stuff of generating lift or foiling through water. They don’t help a boat float or navigate. Think of chainplates as anchors, they merely connect. They are part of the virtual engineering chain that manages the enormous loads of a large boat moving through wind and water. Chainplates do their work using bronze, stainless steel, aluminum and composite materials like fiberglass and carbon fiber.

Chainplates may be brave. They may be fearless. But they take some effort to understand. That makes now the time of chainplate’s secrets.

And what it takes to tell a good one from a bad one.

Right Plate In The Right Place

The big story to tell about these highly loaded anchors is how we match the right material to the right job. For centuries it was metals like iron and steel thru-bolted to heavy wood structure that were the materials of choice. But we live in the Space Age of FRP composites. In these days newer plastics and fibers are finding their way into the chainplate food chain. The trick with these modern attachment systems is understanding how different materials affect each other when they are next to each other.

The crux is how one material communicates with another.

Mostly, chainplates made of contrasting substances are friendly, team players. The conversation between a fore stay and a stem is usually genial. But over time, that polite back and forth can turn into ugly chatter. And corrosion — the cancer of all things that float — breaks out. Corrosion can happen when two dissimilar metals are placed side by side. We boatnerds go so far as to measure and rank the “nobility” of the metallurgical spectrum of the corrosive power of conflicting materials: Steel to copper. Aluminum to Iron. Iron to Bronze. Each pairing enables corrosion in its own way. Each is a Halloween’s Eve of ghoulish what-ifs and failure scenarios.

The other story with chainplates is what it takes to patrol the borders between various materials. Will the rubber sealing compounds quietly let water creep in over its borders and bring rot and ruin to a wood or fiberglass hull? Will that metal plate start creeping away from common sealing compounds used in a cored fiberglass structure? We play the role of surveyors of these long boundaries, and stave off the material civil war that delaminates and destroys hulls.

Stainless chainplates for example are strong and sturdy. But they can be tricky when creating a long-lasting watertight boundary. The main gremlin with stainless is the thermal expansion that ultimately loosens the watertight bond between plate and hull.

To see what it takes to engineer around this threat, let’s take a look at Isobel and her seriously high-tech chainplates.

A Chainplate for All Seasons.

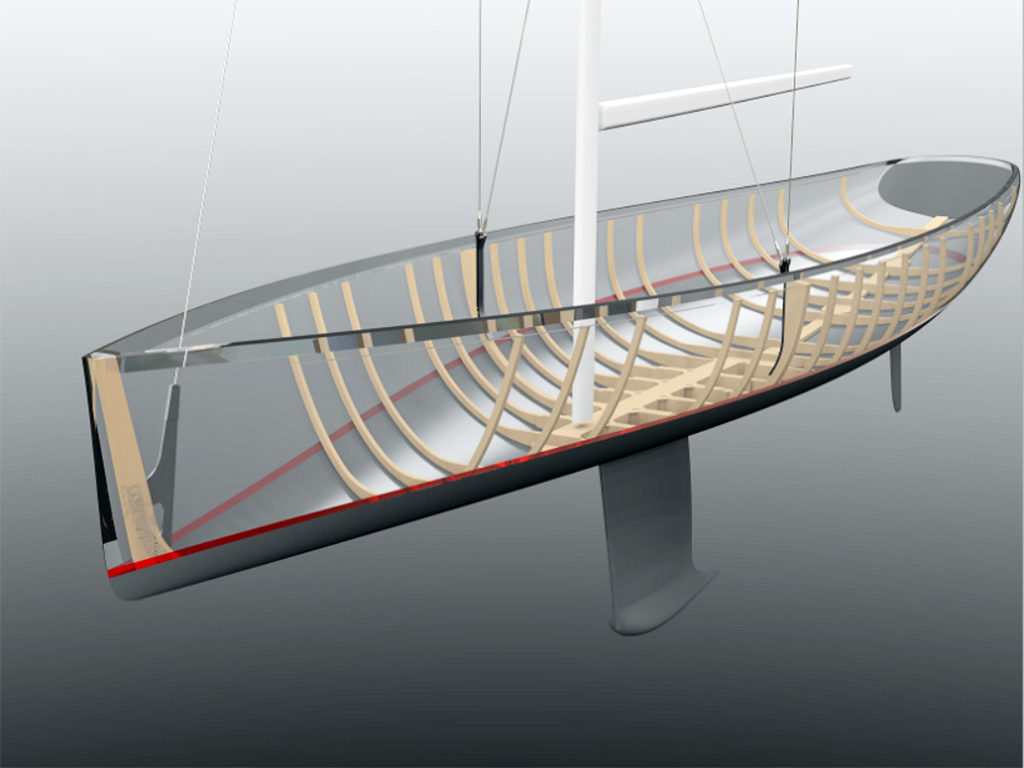

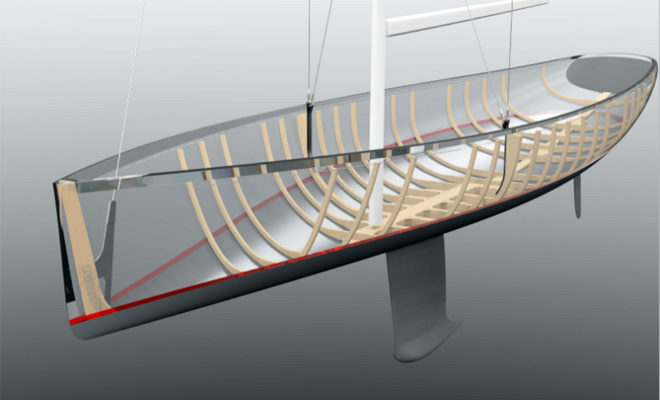

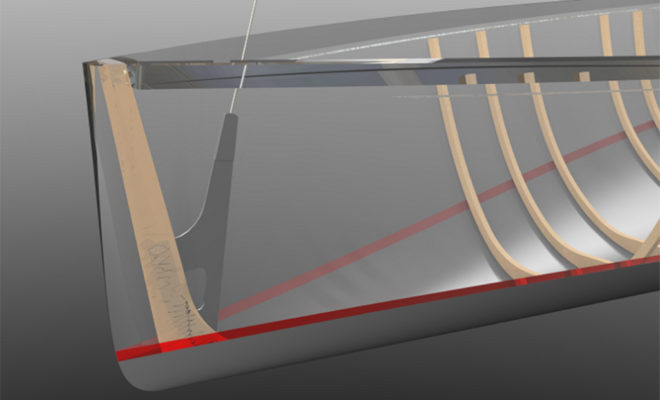

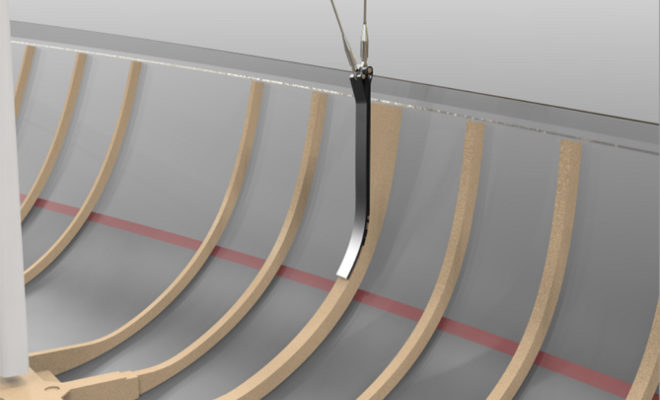

Isobel is a fully-engineered composite thoroughbred. She’s 68 glorious feet of composite wood, carbon, foam, metal, and fiberglass. It was just another magic trick up sleeve fitting her with all-composite chainplates that specifically address each independent job. Look at Isobel’s bow and the complex shaping of her stem as the two sides of the hull come together. See how the surfaces must come together in a skinny, yet shapely front end. Try to imagine what it would take to make a strong-enough anchor for her powerful rig that fits into that shape. We looked at a complicated custom-crafted welded stainless plate that could contort into this tricky shape. Expensive and prone to troubles down the road. Thinking outside the box, we realized a simpler cheaper answer: split that wooden stem shape down the center, and bond in a composite plate custom-crafted and formed to smoothly accept the angle of the forestay.

Better yet, that shape could be water-jet cut from a simple, low-cost G-10 glass-reinforced-epoxy sheet. The result is a strong, efficient, gloriously water-tight chainplate that is downright cheap to make and powerful in its execution of spreading the load through the stem.

Read the rest of this article on stephenswaring.com to learn how sideplates are engineered for optimal load distribution.